Overview

Solutions for most problems that Qualimations handles are derived and solved using analytical methods. These solutions prove to be very useful and provide excellent insight into the behaviour of many systems. DOE allows for multiple input factors to be manipulated determining their effect on a desired output (response). By manipulating multiple inputs at the same time, DOE can identify important interactions that may be missed when experimenting with one factor at a time. All possible combinations can be investigated using the DOE apprach. Qualimation has several samples of successful implementation of the DOE tool in the quality improvement program. We also suggest you when not to use these methods and to start resorting to other means of analysis.

Design of experiments is a very powerful tool that can be utilized in all manufacturing/service industries. Quality managers who encourage DOE use will greatly increase their chances for making breakthrough improvements in product quality and process efficiency.

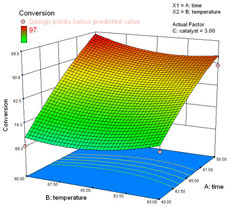

Design of Experiments (DOE) techniques enable designers to determine simultaneously the individual and interactive effects of many factors that could affect the output results in any design. DOE also provides a full insight of interaction between design elements; therefore, helping turn any standard design into a robust one.

In brief, DOE helps to pin point the sensitive parts and sensitive areas in your designs that cause problems in Yield. Designers then are able to fix them and produce robust and higher yield designs prior going into production.

What is Designed Experiments ?

Every factor operates at different levels or stages during a process. These levels are either determined so that the process adds value to the product and hence there is a value associated with it. As an example, a flight management over booking could be set at two levels, one which takes low levels of risk and other which takes high risk. The factor here is risk, the levels are low and high. When you bake a cake, the factor are temperature and time in the oven, you could keep at high temperature or low temperature and this can be done at several levels of time. The objective in this experiment is to make a perfect cake. The factors that contribute value, like temperature and time are also the same factors that contribute to the issue or problem... Read More

Course Details :

Week 1

- * Design of Experiments (DOE) And Industry

- * How to use DOE

- * What is meant by Designing an Experiment ?

- * Understanding Interactions

- * Overview of basic statistical concepts

- * Basic concepts of Parameter designing

- * Setting the Objectives

- * Analysis of Variance

- * One and two Factor Experiments

- * Factorial effects and plots

- * Model evaluation and Equations

- * Residual Analysis and Normal Probability plots

- * Hypothesis Testing t and f tests

- * What is meant by setting optimal points.

WEEK 2

Module 1

- * Factorial Design

- * Modelling and Equations

- * Multi factor Experiments

- * Graphical representation of 2 power designs

- * Concepts of Confounding

- * Resolution III, IV and V designs

Module 2 : THE ROBUST DESIGN

- * The basics of robust designs

- * Taguchis Signal-Noise

- * Taguchi designs

- * Robust design example and applications

- * Orthogonal Arrays and how to apply in industry

Module 3 : THE RESPONSE SURFACE METHODOLOGY

- * From first-order experiments to second-order experiments

- * Analysis of second-order response surfaces

- * Central composite designs

- * Box-Behnken design

- * Process optimization

- * Science of inference and planning

" Perfect,Interesting and highly educative. It has broaden my knowledge on how to handle, solve problems and improve quality in my organization "

Julie O Kodu , protocol manager/project co ordinator, Sea Petroleum & CTAS Group of companies,Lagos,Nigeria

Warranty Analysis

Warranty Analysis focuses on predicting future warranty and maintenance cost of running the whole program. At Qualimation Tech we have developed methods that helps in early detection and correction of some of the warranty related problems also this Information is needed to perform root cause analysis on product failures. Since field failure forms as basis for FMEA, study of warranty is essential to the quality managment process. The Warranty information also forms as basis to feed subsystem and component level reliability information... Read More

NDT Preparation

Now you don't have to leave your place and travel, you could choose a range of online courses. The course material would reach you by post and also as a mail attachment

Once you are part of the Qualimation family, all doubts pertaining to NDT and Quality will be taken care by our experts.

Our experienced staff of consultants have developed a full range of customised NDT training modules for you. All our products are based on years of practical real-world experience working.. Read More

We Provide

As part of the NDT training course we provide you the following:

World Class training

Training Manual

Practical Check Sheets

Online and On Call Support any time ( call for any doupts from site or field )

NDT Consulting

Qualified ASNT Engineers with NDT L-III in 5 methods ( UT, RT, PT, MT & VT).Over 1000 hrs experience in Training personnel in NDT... Read More

NDT Course at Chennai,TN

1st Sep to 1st Nov Black Belt Six Sigma, Online, WhatsApp: +91 98950 93119

E. : info@qualimations.com

Reg. Chennai: +91 9940622700

Reg.Online: Register for the Next Course