Overview

The need for organizations to carefully monitor the quality of their products and services is no longer a optional in today's economy. In order to maintain consistent quality standards, everyone must utilize techniques that are more advanced than their competitors.

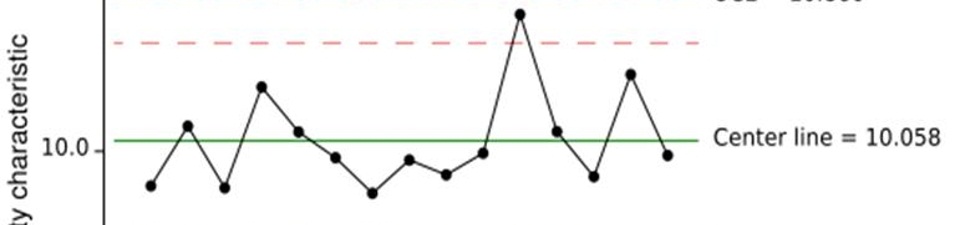

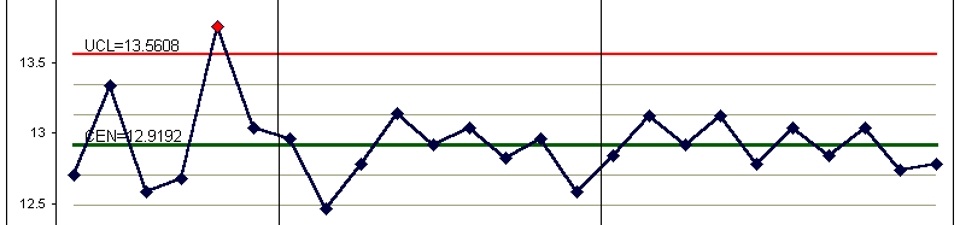

In all processes, we need to monitor the extent to which our products meet specifications. The deviations from target specifications, and excessive variability around target specifications. SPC is a very effective tool that helps us in controlling the Quality of the product.

The application of SPC methods has become well established in aerospace, automotive, electronics, pharmaceutical, semiconductor, and other manufacturing industries.

Today, these methods are also being explored by the services industry, including banks, insurance companies, government agencies, and health care organizations.

Take the SPC course and become an expert in controlling:Module 1 :

- * What is a variable in a process and how to measure stability of a process?

- * What is a out of control state and what are the types of causes?

- * What is meant by characteristic control and what are attributes?

- * How to derive the process average and standard deviation?

- * What is the philosophy behind control charts and what are the types of charts?

- * What is Deming's 14 points?

- * What is the six sigma philosophy and what are parts per millions?

- * Detailed discussion on Assumptions in SPC and its limitations.

- * What is a rational subgroup?,and what is its relation to the control charts?

Module 2 :

- * How to develop control charts for Attributes and variables?

- * What is machine capability ?

- * What is process capability?

- * How to collect data for plotting the control charts?

- * Company wide SPC implementation.

- * Cause and effect analysis.

- * What is composite capability index and how is it measures?

- * Case Study-1

- *Case Study-2

NEED FOR SPC

You need SPC in the following situations

- a When controlling ongoing processes by finding and correcting problems as they occur.

- b When predicting the expected range of outcomes from a process.

- c When determining whether a process is stable (in statistical control).

- d When analyzing patterns of process variation from special causes (non-routine events) or common causes (built into the process).

- e When determining whether your quality improvement project should aim to prevent specific problems or to make fundamental changes to the process.

SPC & SIX SIGMA

SPC is an important component of any Six Sigma program and the first choice in improving and controlling the processes. Learn the power of SPC through us....

- * Identify what characteristics to be controlled

- * Establish Control limits

- * Find how to control the process

- * Learn how to measure improvement of a process

- * Learn how to detect shift and how to set alerts that take action.

Learn about the two types of causes that affect your variation. This aids you in your problem solving and decision making process. The two causes are chance and assignable. The chance cause is intrinsic to the process and will always be present. The assignable cause stems from external sources and indicates that the process is out of statistical control. Learn more on how to control these sources of variation.

Objective

Based on experience & competency in the NDT methods personnel are Qualified as